私たちは業界です

Mooring tails are an essential component of a mooring system, providing the necessary elasticity and shock absorption to secure a vessel in place. The quality of mooring tails can have a significant impact on the safety and stability of the mooring operation. In order to ensure a reliable and durable mooring system, it is important to consider the following characteristics of quality mooring tails:

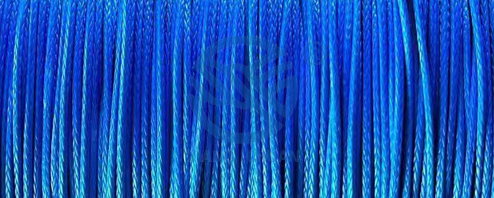

1. Material: The material used in the construction of mooring tails plays a crucial role in determining their strength, durability, and resistance to environmental factors. Quality mooring tails are typically made from high-quality synthetic fibers such as polyester, nylon, or polypropylene. These materials are known for their high tensile strength, abrasion resistance, and UV-stability, making them ideal for marine applications.

2. Construction: The construction of mooring tails should be carefully designed to withstand the dynamic loads and stresses experienced during mooring operations. Quality mooring tails are typically constructed using techniques such as double braid or three-strand construction, which enhances their strength, flexibility, and resistance to abrasion. Additionally, mooring tails should be properly spliced and finished to ensure maximum strength and durability.

3. Length and Diameter: The length and diameter of mooring tails should be carefully selected based on the size and weight of the vessel, as well as the environmental conditions at the mooring site. Quality mooring tails are typically available in a range of lengths and diameters to accommodate different mooring requirements. It is important to choose mooring tails that are long enough to provide sufficient elasticity and stretch, while also being thick enough to withstand the forces exerted during mooring operations.

4. Elasticity and Stretch: The elasticity and stretch of mooring tails are critical factors in their ability to absorb shock loads and prevent sudden jerks or snatching movements during mooring operations. Quality mooring tails should have a high level of elasticity and stretch, allowing them to stretch and recover without losing their strength or shape. This ensures a smooth and controlled mooring process, reducing the risk of damage to the vessel or mooring equipment.

5. Resistance to Abrasion and UV Exposure: Mooring tails are constantly exposed to harsh marine environments, including saltwater, UV radiation, and abrasive surfaces. Quality mooring tails should be designed to withstand these environmental factors and maintain their strength and integrity over time. UV-stabilized materials and protective coatings can help to enhance the resistance of mooring tails to UV exposure, while abrasion-resistant materials and construction techniques can minimize wear and tear during mooring operations.

6. Buoyancy: In some cases, mooring tails may need to provide additional buoyancy to help support the weight of the vessel and maintain a safe mooring position. Quality mooring tails may incorporate buoyant materials or designs to provide the necessary buoyancy without compromising their strength or flexibility. This can be particularly important for larger vessels or mooring systems in exposed or high-current areas.

Overall, the characteristics of quality mooring tails can have a significant impact on the safety, reliability, and performance of a mooring system. By selecting mooring tails that are made from high-quality materials, constructed with care, and designed to withstand the demands of marine environments, vessel owners can ensure a secure and stable mooring operation for their vessels. It is important to consider these key characteristics when choosing mooring tails to ensure a successful and efficient mooring system.

住所:

中国江蘇省宝営県城南工業園区城南路8号

Eメール:

E-mail1:vanzer@xcrope.com Vanzer Tao

E-mail2:sales@xcrope.com Wang Peng

E-mail3:grace@xcrope.com Grace Li

E-mail4:info@xcrope.com David Cheng

会社電話:

+86-514-88253368

海外営業部:

+86-514-88302931

著作権 © Jiangsu Xiangchuan Rope Technology Co., Ltd. |無断転載を禁じます